EAGLEYE QRD

QUALITY REPORT DESIGNER

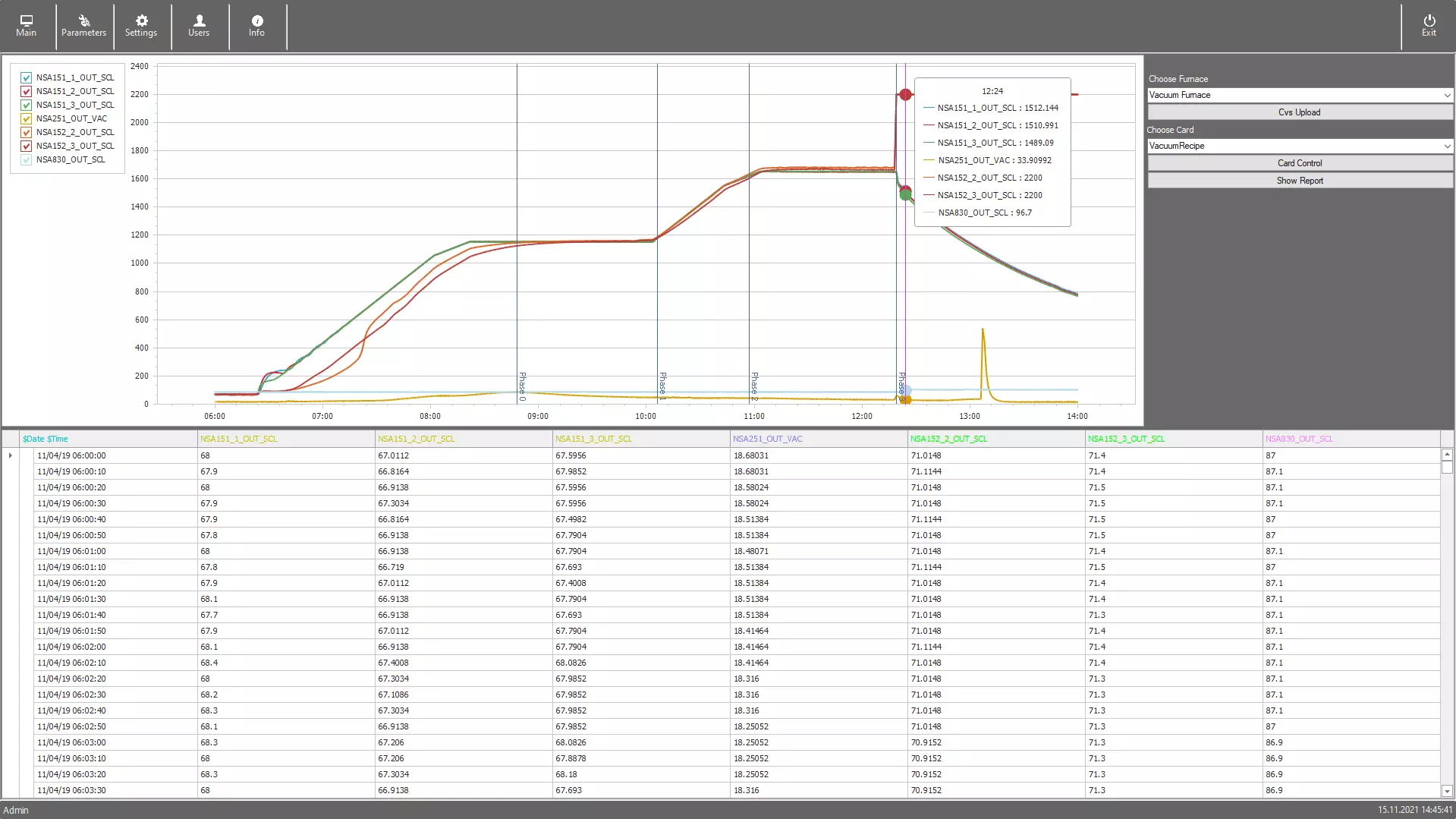

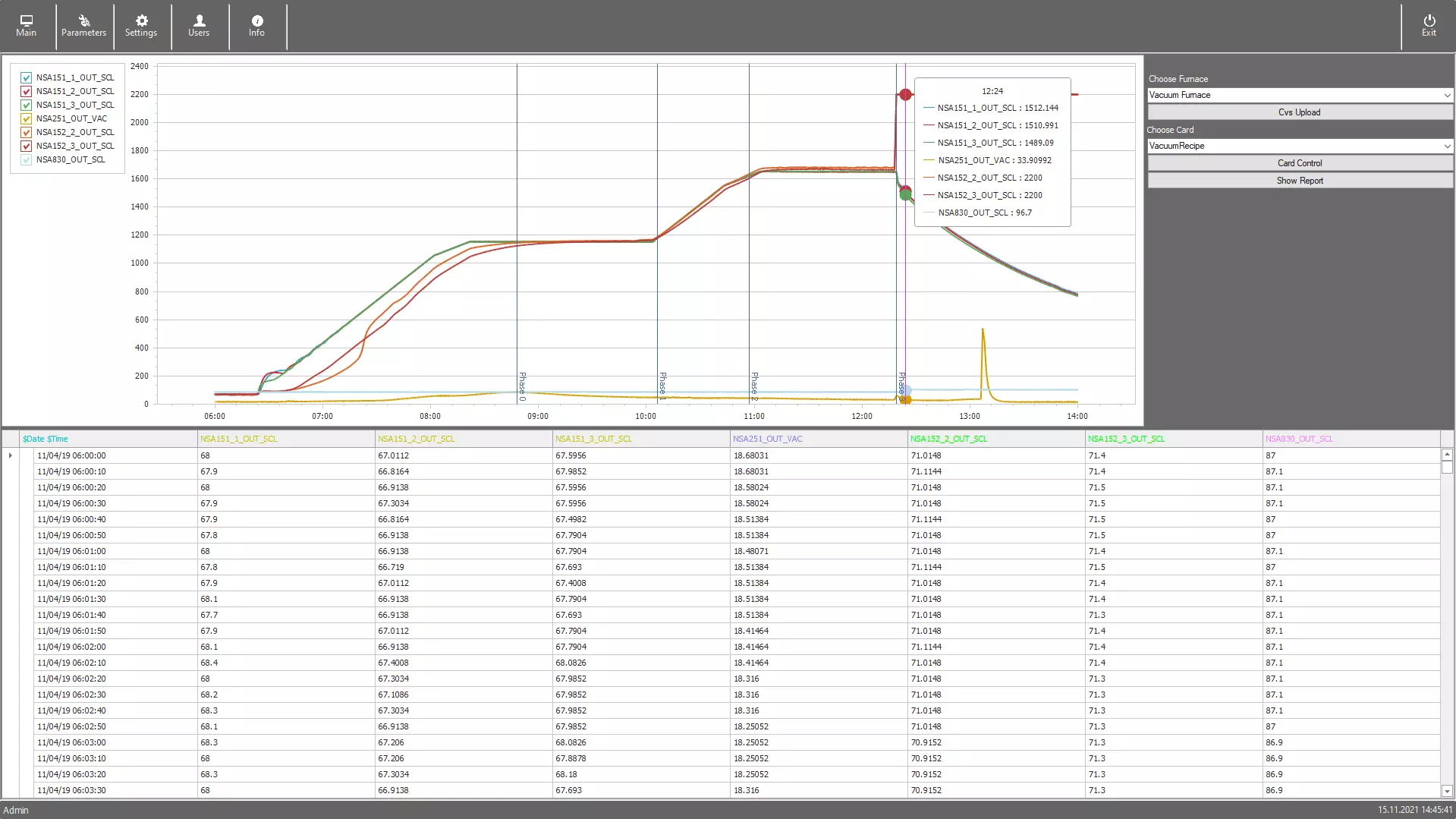

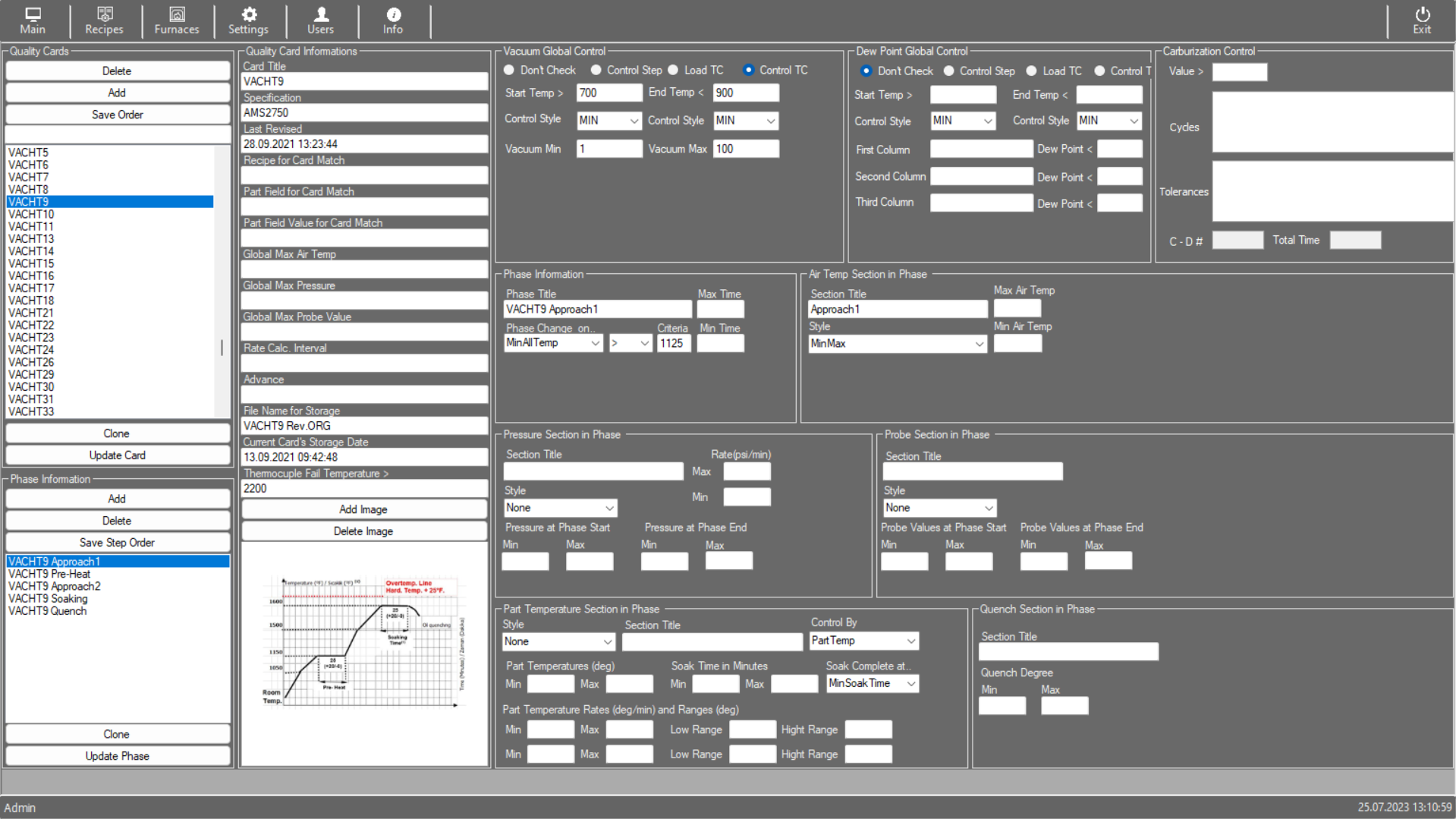

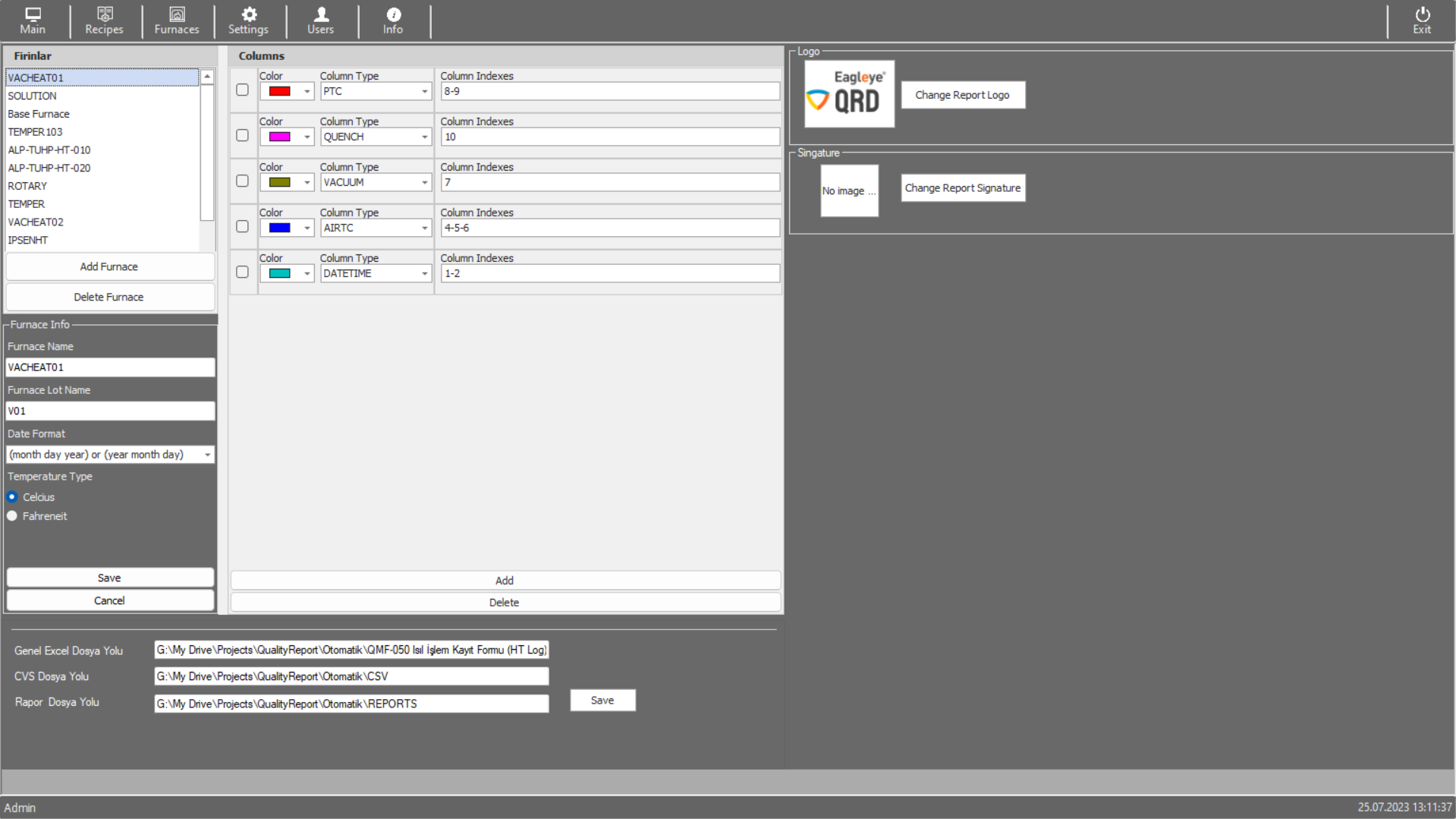

Eagleye QRD automatically verifies and reports on the conformance of the data received from the furnaces to the desired quality cards, including AMS2750, CQI-9, and NADCAP. Process data can be imported from a table, received directly from the field, or linked to an enterprise resource planning system. In this manner, you can evaluate your process and conduct checks that would normally take hours in mere seconds. The quality reports and results are emailed to you following the simultaneous inspection of dozens of machines operating in your facility from a central location. In addition to the procedure being shortened, the risk of making errors is eliminated.