GOING AFTER DEVELOPMENT AT ALL TIMES THANKS TO ITS 40 YEARS OF EXPERIENCE: SİSTEM TEKNİK

A firm that takes steps forward with determination, always pursues innovation and believes in continuous improvement with its investments in R&D; Sistem Teknik. Our cooperation with 3E Industrial, has been continuing for a long time.

Could you tell us about your company and solutions? Which sectors do you mainly provide services to?

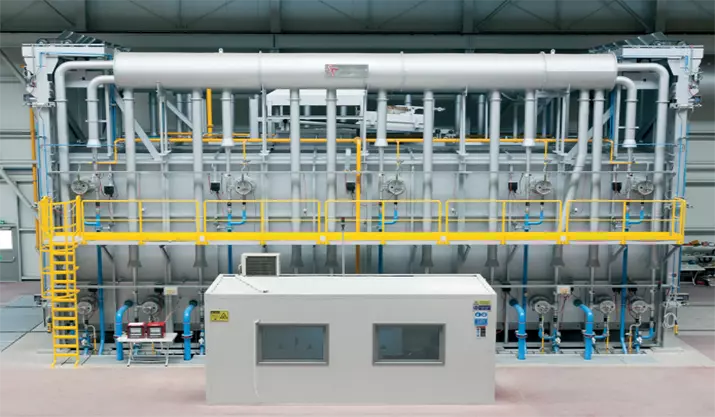

We, Sistem Teknik AS. family, produce furnaces that are 100% compatible with AMS, NAD-CAP, CQI requirements for

the industrial heat treatment needs of our customers by using innovative solutions with our 40 years of experience,

and young, strong and dynamic staff. We can classify our production areas under the following headings:

• Heat treatment furnaces for aerospace and defense industry

• Vacuum heat treatment, LPC and Vacuum Oil Quench furnaces

• Tempering, nitration, brazing, thermodiffusion applications

• Cart bottom and chamber type furnaces for forging, annealing, normalization applications

• PWHT, stress relieving, tempering and hardening heat treatment applications

• Microwave drying furnaces

• Automatic gas generators

• Special furnaces and heat treatment facilities

In addition, we provide solutions by conducting R&D studies according to special demands. We keep in touch with our customers all the time and provide after-sales service support in the fastest and most reliable way in case of problems.

How did your paths cross with 3E Industrial? What was the main drive in your choice of Eagl

We have been working with 3E Industrial since its establishment in 2005. 3E Industrial offers a solution partnership to our needs with features such as the Eagleye RSD software's graphical interface, monitoring system, alarm system, data collection, analysis and reporting systems in the SCADA systems of our furnaces.

What did you get from this choice?

In our automation systems in our furnaces, we see that the Eagl

How do you use Eagl

Thanks to Eagl

OUR FIRM HAS BEEN EXECUTING VARIOUS R&D STUDIES FOCUSED ON INCREASING AVAILABILITY

AND FUNCTIONALITY AND ENERGY EFFICIENCY THROUGH SIMULATION AND MATHEMATICAL MODELING BEFORE MANUFACTURING PHASE.

What do you think is the most important factor in working with 3E Industrial?

First of all, we believe in the importance of customer satisfaction. For this reason, the most important factors are that we receive positive feedback

from our customers and increase customer satisfaction with Eagl

We would like to get information about your R&D activities.

Our company always follows the innovations and needs in the industrial furnace sector in the world. In technology that is constantly evolving, we, as Sistem Teknik family, work continuously and devotedly to meet the needs by following the innovations.

We work on furnaces that can perform complex processes such as Microwave Drying Furnace, Vacuum-Oil Hardening Heat Treatment Furnace, and we conduct R&D studies by conducting literature, design, analysis and field research for many products we can use.

Our furnaces carry out various R&D studies focusing on increasing their usability, functionality and energy efficiency with simulation and mathematical modeling methods before they reach the manufacturing stage.

What kind of company strategy did you adopt during the COVID-19 process and the new normal?

As an organization providing services worldwide, Sistem Teknik A.S. have been affected by the COVID-19 pandemic as many other industries. Considering the health of our employees, we created action plans to prevent the pandemic within the company and provided the necessary tools. With the new normal, as you know, many organizations have switched to remote working. We also started to hold our meetings online and we quickly adapted to this process. We hope to overcome this process as soon as possible..

Finally, what are your goals for the future?

As Sistem Teknik AS, we have been continuously increasing our product range since the day we started. In order to improve our products and add new ones to our product range, we aim to increase the engineering studies that we continue our activities in our R&D center.

Writer

İlker Demir

Software & Automation Engineer