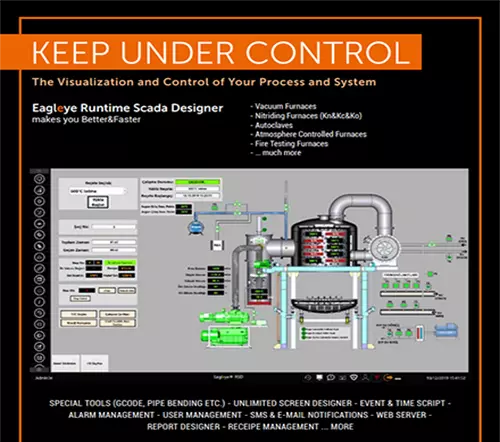

A NEW CONVENIENT & INNOVATIVE SCADA SOLUTION; EAGLE YE RSD® BY 3E INDUSTRIAL ENGINEERING

3E Industrial Engineering, the company where the years of innovation and experience converges with perfect engineering knowledge.

After analyzing the needs of automation industry for years, 3E Industrial Engineering designed the Eagle ye RSD® so that their clients can

customize their own user interfaces however they wish with specialized solutions.

We would like to be acquainted with your company, could you explain your product to us?

Our company 3E Industrial Engineering is established in 2005 for providing prime & qualified services for automation and coding industry. 3E stands for “Expert”, “Exclusive” and “Engineering”. Founder of our company, Gokhan Lale achieved the first steps of our company’s foundation thanks to his education in Tuzla Technical Highschool and his Electrical Engineering education in Kocaeli University. With his years of experience in the industry he guided our company’s business scope. Since our first day of action we became a solution partner for more than hundreds of projects over 30 countries.

In year 2008 we started to develop the Eagl

After we developed the Eagl

Since the first day of establishment, our company had the main goal of developing its own SCADA designer and with Eagl

BRIEFLY EAGLEYE RSD® IS A PRODUCT OF YEARS OF KNOWLEDGE TURNED IN TO AN EASY TO USE SOFTWARE WITH MANY SPECIALIZED FUNCTIONS FOR ANY PROBLEM THAT YOU MAY ENCOUNTER

Could you elaborate the Eagl

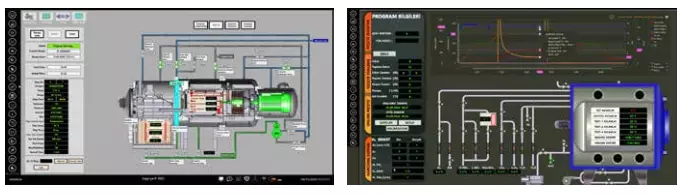

As you might noticed, our products acronym is formed by the initial letters of Runtime SCADA Designer.

Eagl

What are the advantages provided to clients of 3E Industrial Engineering with, Eagl

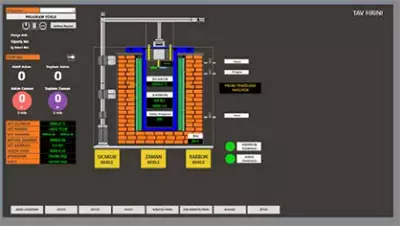

While we were developing the Eagleye RSD® our main goal was to provide an easy to use, user friendly

software which also can deliver many solutions for many different problems. We integrated lots of customizable solutions to our software

regarding to our user’s needs which many of these solutions aren’t even situated in any other SCADA softwares.

Furthermore, this also shows that we can integrate any special addition requests made by our customers on any occasion.

We can assure you that with Eagl

BRIEFLY EAGLEYE RSD® IS A PRODUCT OF YEARS OF KNOWLEDGE TURNED IN TO AN EASY TO USE SOFTWARE WITH MANY SPECIALIZED FUNCTIONS FOR ANY PROBLEM THAT YOU MAY ENCOUNTER

Between these solutions, do you have any success stories about machine industry you would like to to share?

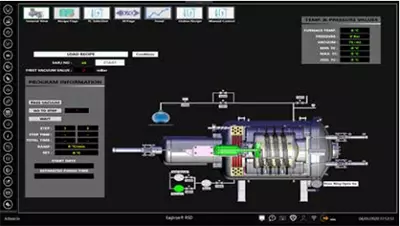

Between the years 2019 & 2020 we used and tested Eagl

What would you say about the importance of SCADA softwares for Industry 4.0 and beyond?

For those machine manufacturers and automation companies who are aware of the dire need of digital transformation, SCADA software usage became almost an obligation. For the past years it was only a necessity in aerospace and automotive industry but now it is a need for many industries. Especially with rise of Industry 4.0 standards acquisition of production data from field and the evaluation of this data became a trending topic for every industrial leader. A SCADA software would help you with control of you machines remotely and it will also help you to evaluate the data acquired from those machines to optimize your production.

Anything you would like to say about your future goals?

With our innovative and convenient software we are hoping to become a solution partner for machine manufacturers and automation companies and spread our software to a global level.

Writer

Meltem Dağdeviren Lale

Commercial Director