EAGLEYE PHT

PORTABLE HEAT TREATMENT

Eagleye PHT, produced with the support of TÜBİTAK and developed with the support of KOSGEB, is always available with process-specific solutions due to the significance we place on research and development.

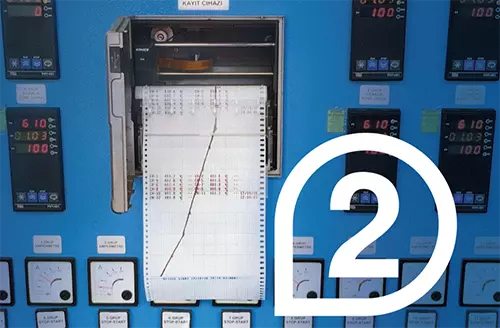

According to the Eagleye PHT control type, three distinct variants can be manufactured: with a temperature control device, an operator panel, and an industrial computer. While our model with a temperature controller can store up to 100 programs in its memory, our models with operator displays and industrial computers can store an unlimited number of programs.

✓ IP 44 is the security class of all of our models.

✓ Each of our models is both 30V and 60V

✓ Ammeters are integrated into the system in order to monitor the current passing through each channel.

✓ All our models are designed to be used automatically and manually.

✓ In our industrial computer model, we have a wireless button option that allows remote control.