ACCESS TO IMMEDIATE INFORMATION

In today's world, where information technologies are evolving at a staggering rate, ensuring the IT adaptation of your facility is essential for the comfort of your business and your clients.

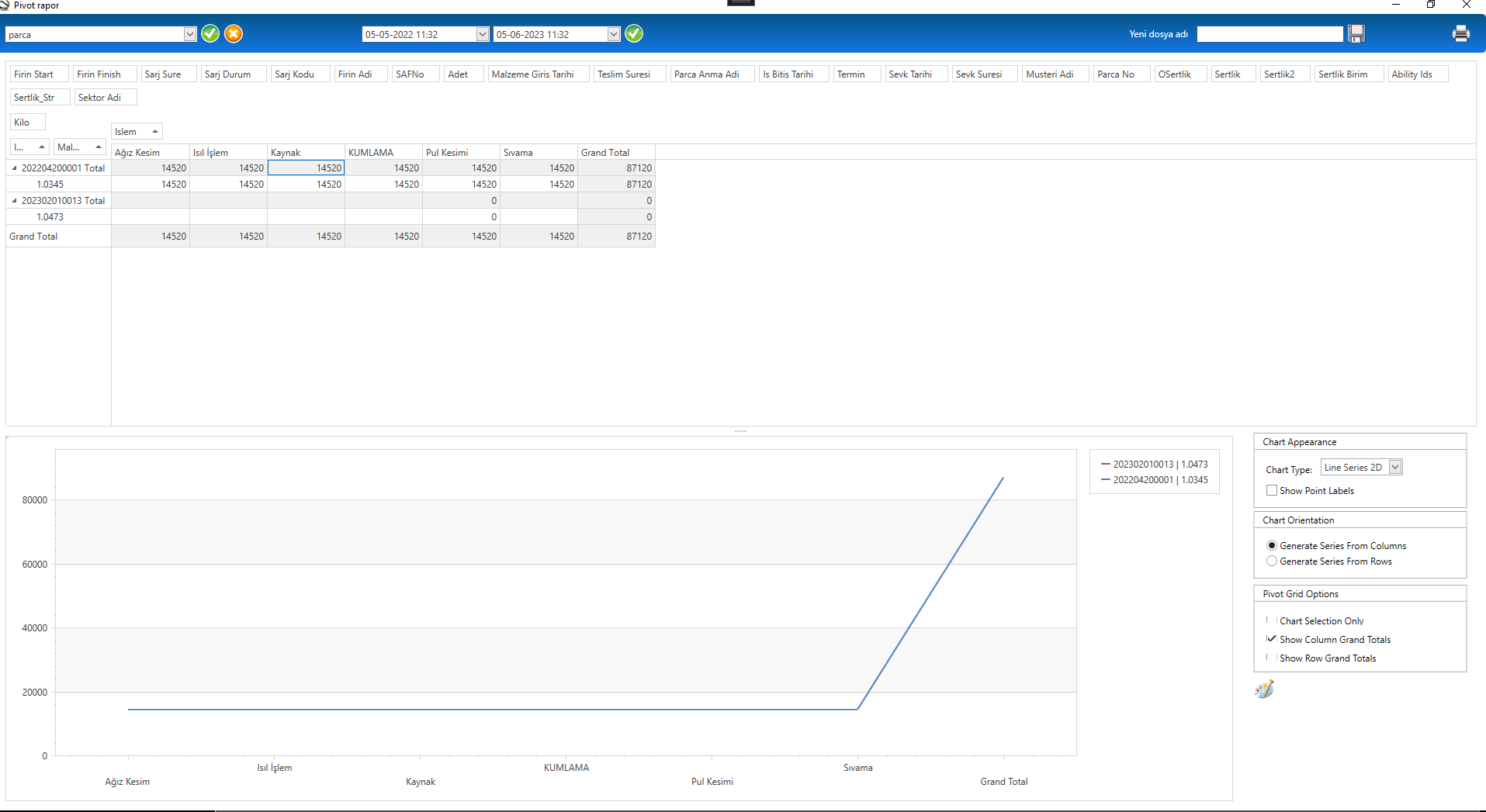

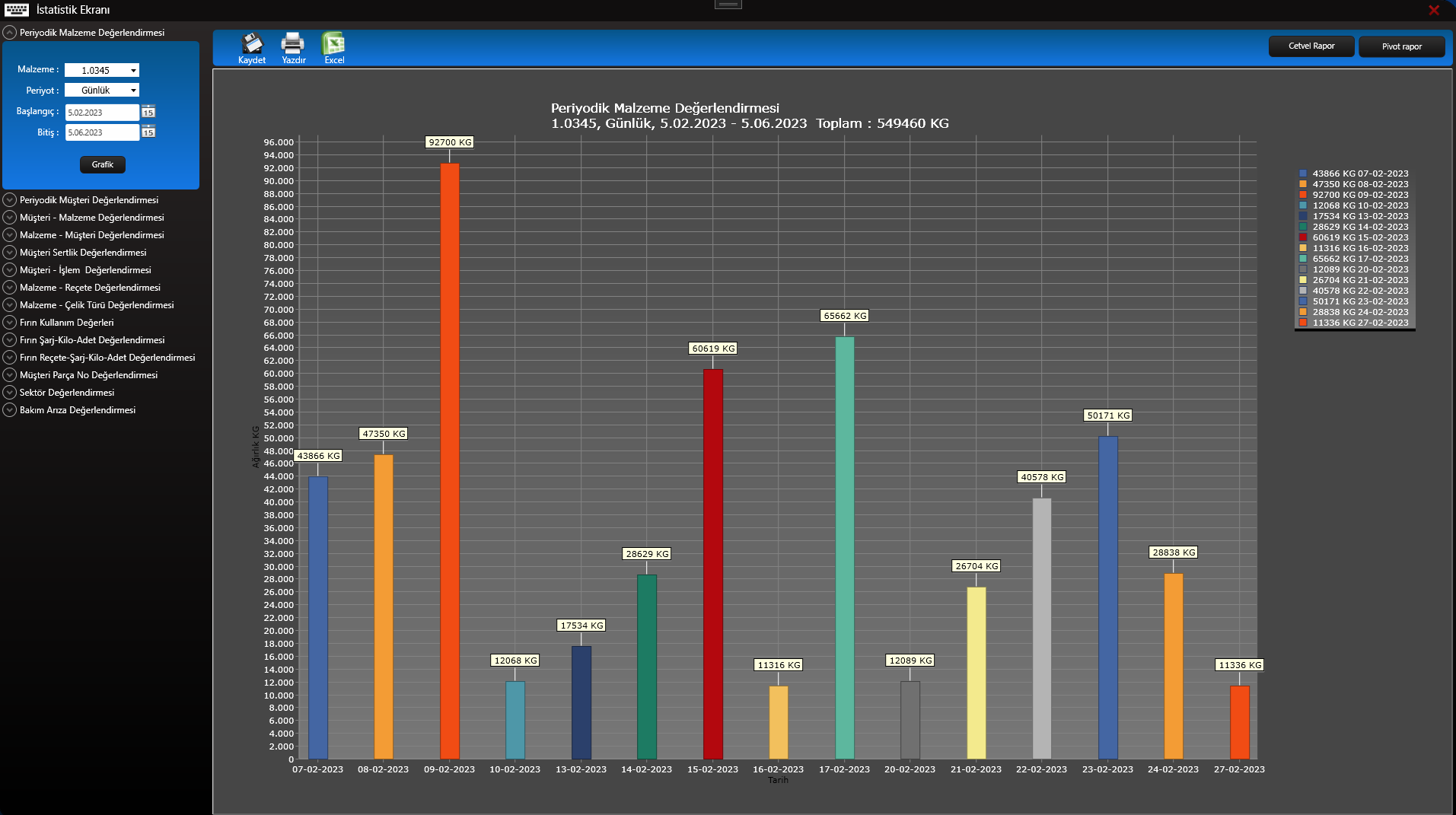

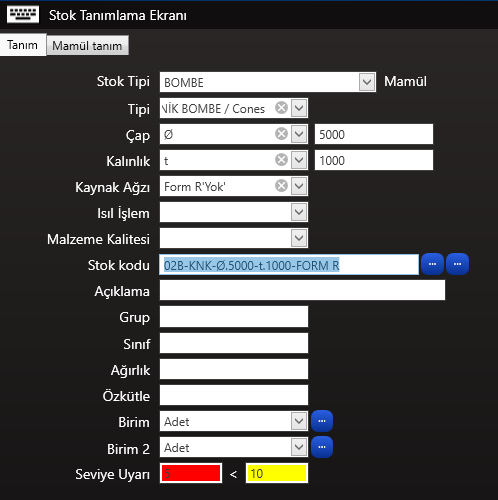

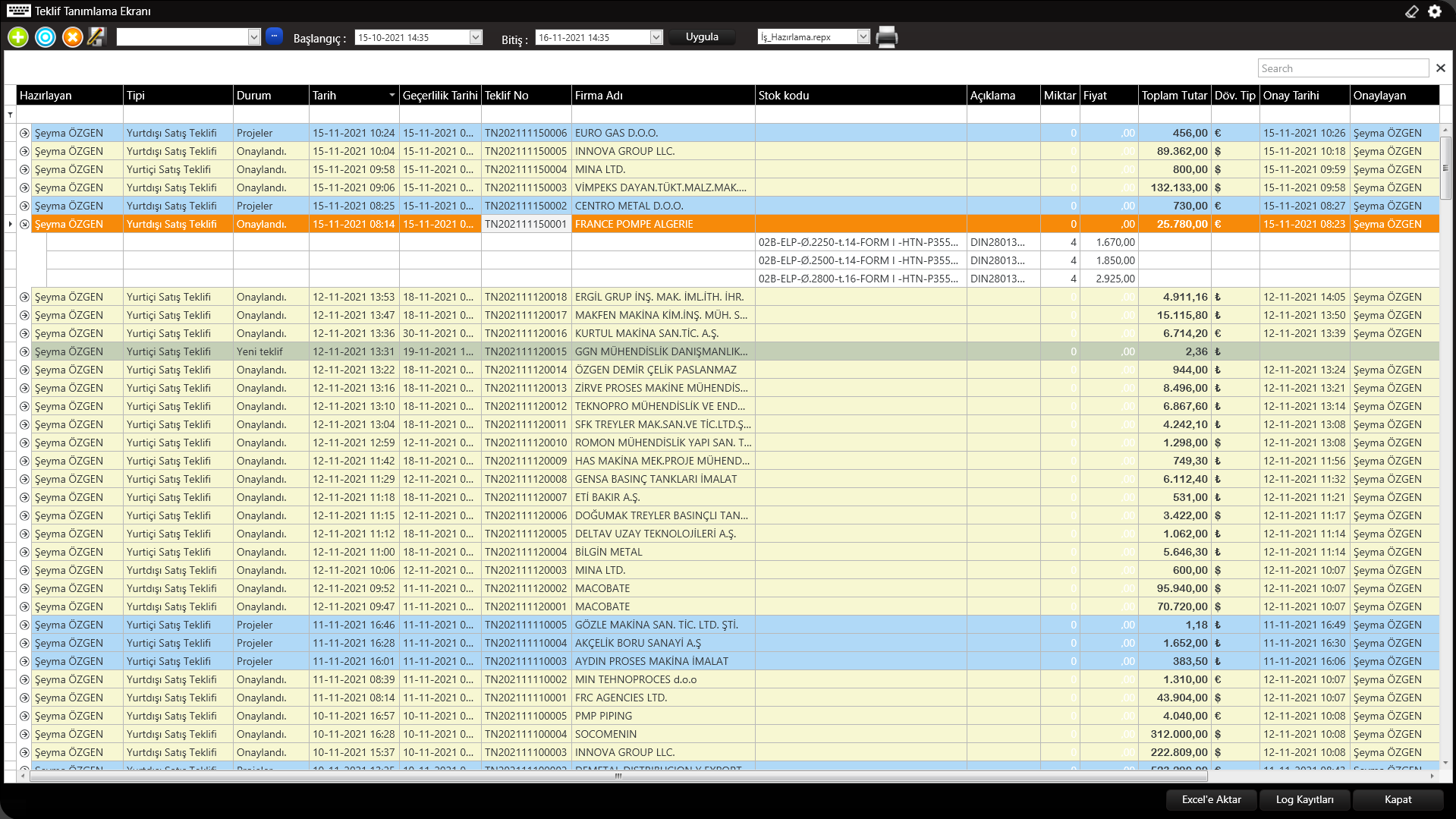

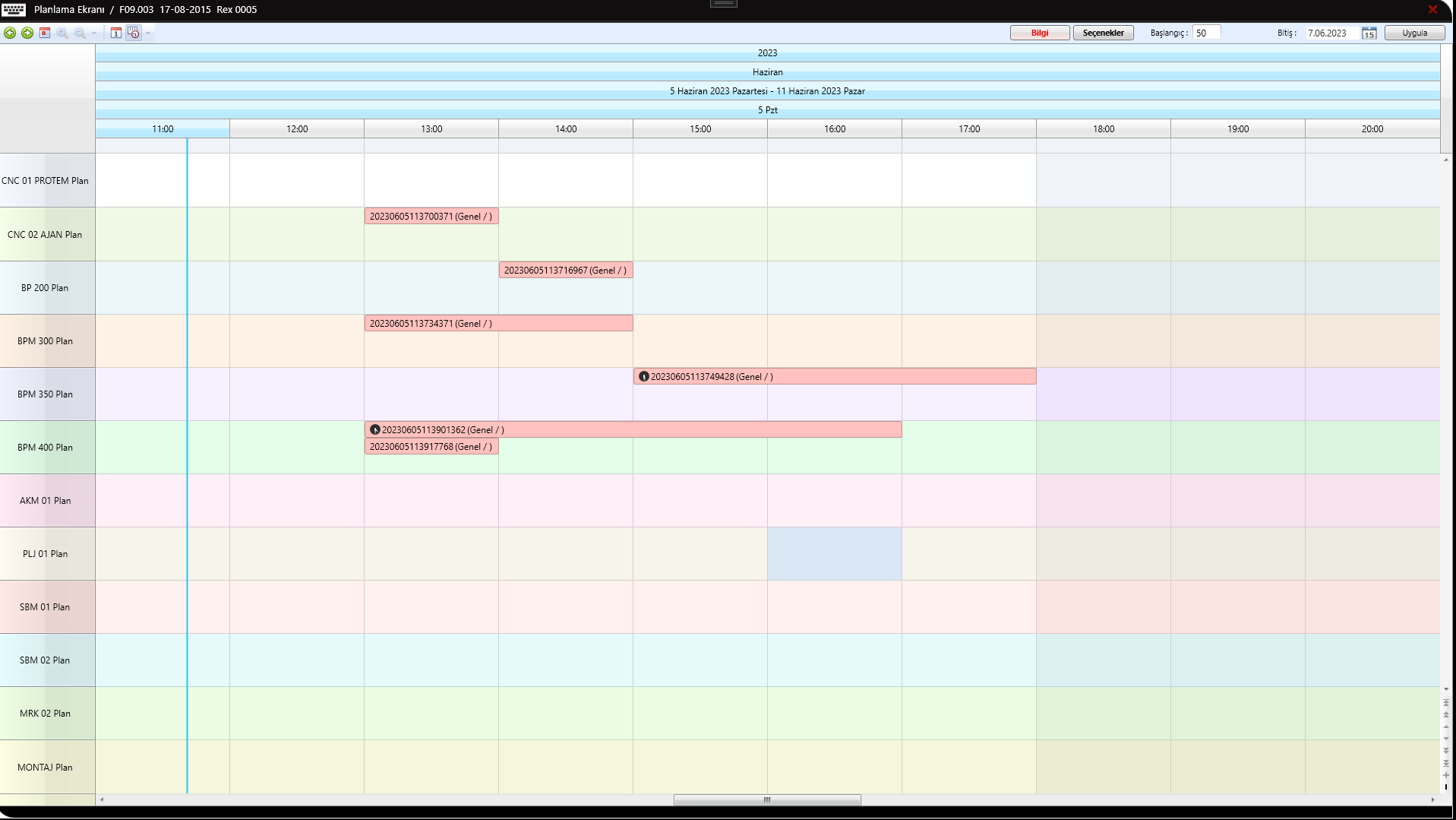

Thanks to HQM, where you have immediate access to all production data and process information, it is now very simple to manage your facility from anywhere.

Thanks to HQM, where you have immediate access to all production data and process information, it is now very simple to manage your facility from anywhere.